Jcsportline is not only the biggest carbon car parts manufacturer,but also your carbon tuning parts solution partner

Crafted from carbon fiber, the components we design and produce a special look along with long-lasting life span. We design every kit vehicle specific, custom body wholesale/sport car body kits wholesale/wide body kit cars wholesalewhich guarantee it matches all the curves and shapes of the particular make and model. For about 10 years we have been investing our efforts on carbon fiber light-weighted applications and OEM production. Our passion and dedication are so inspiring that our customers get attracted to visit our manufacturing plant. We always welcome with open-heart to encourage customers to take a trip to our advanced working plant and meet our dedicated and enthusiastic team of professionals and workers.

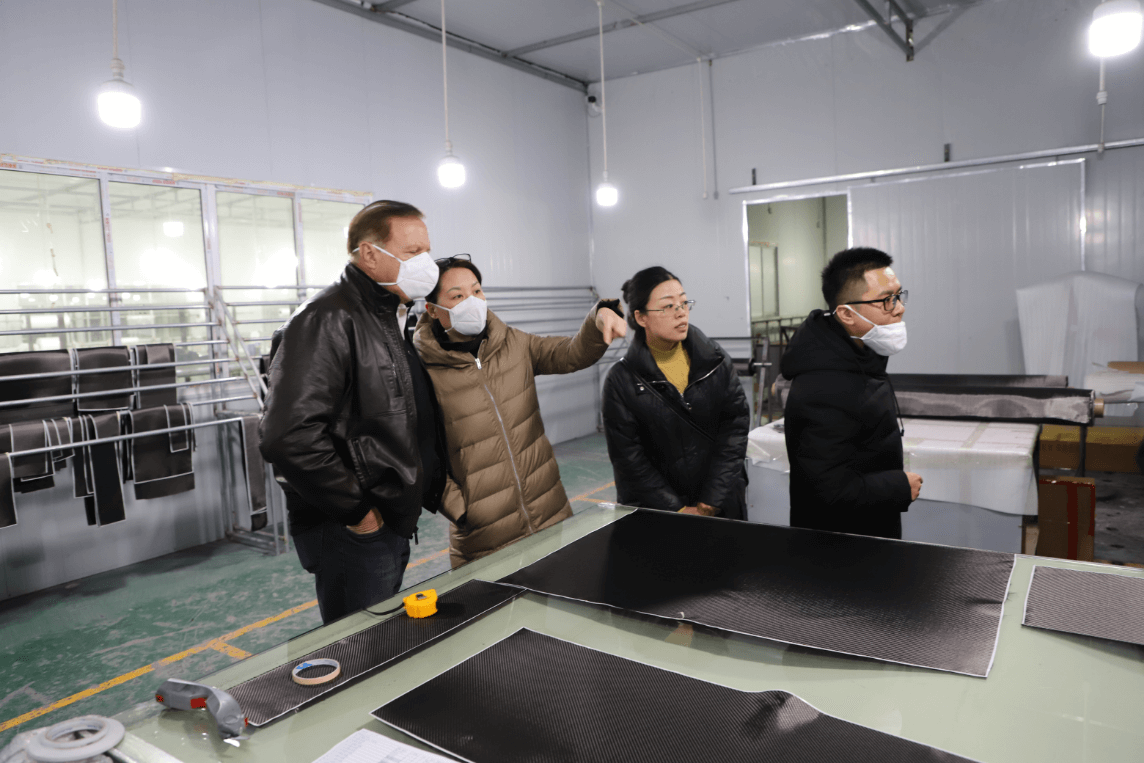

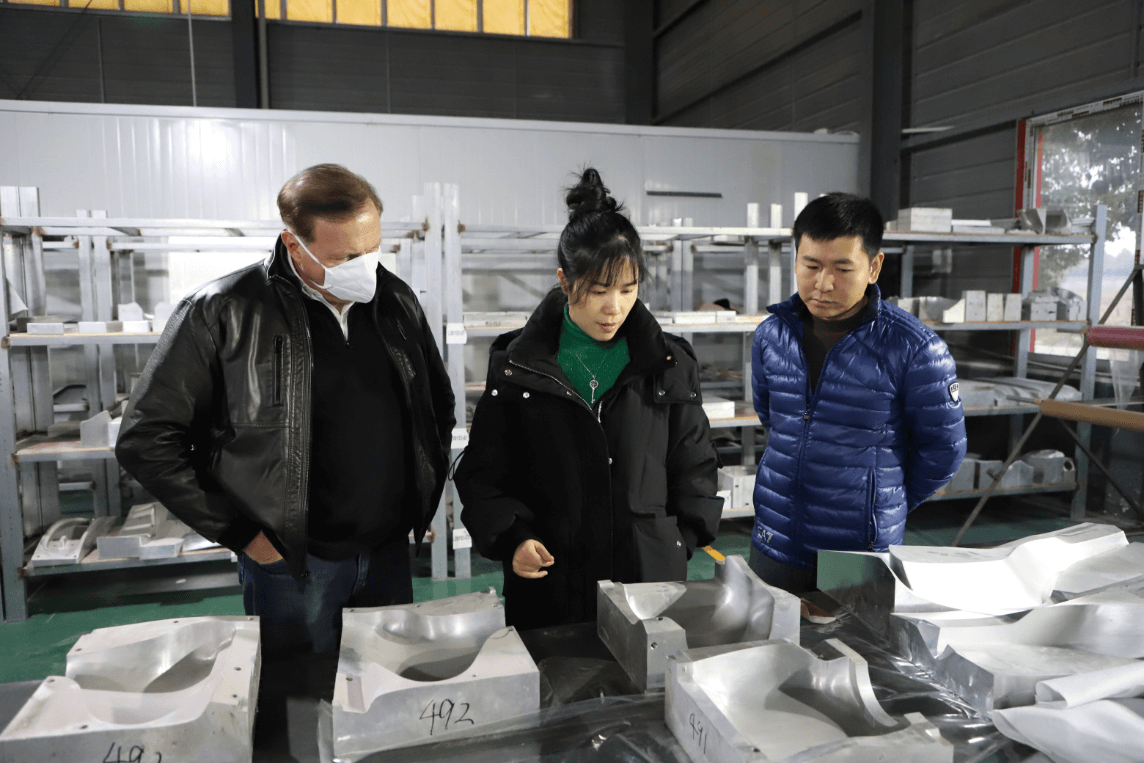

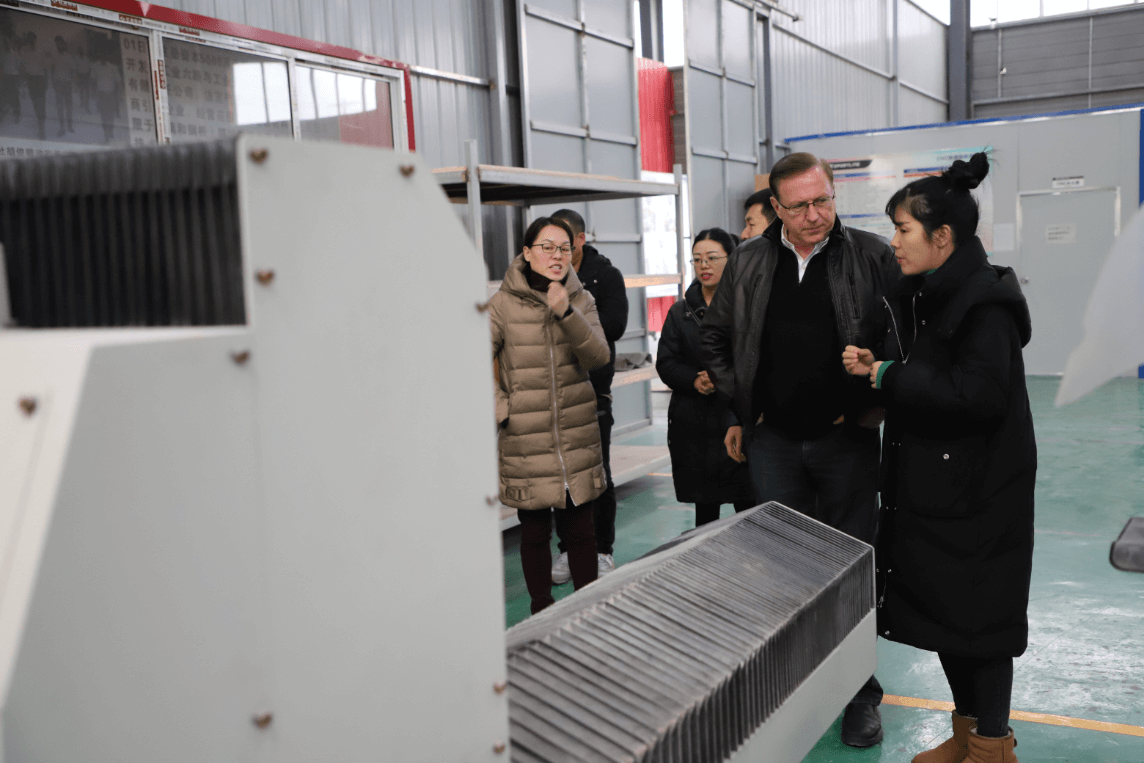

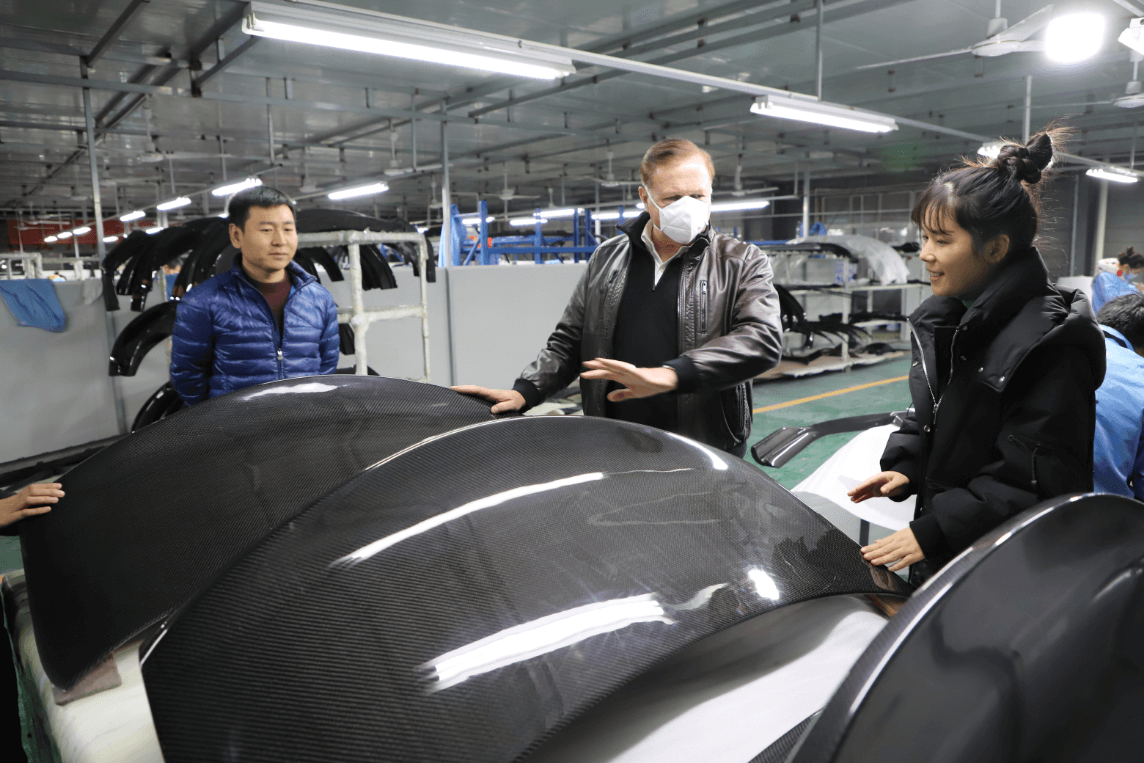

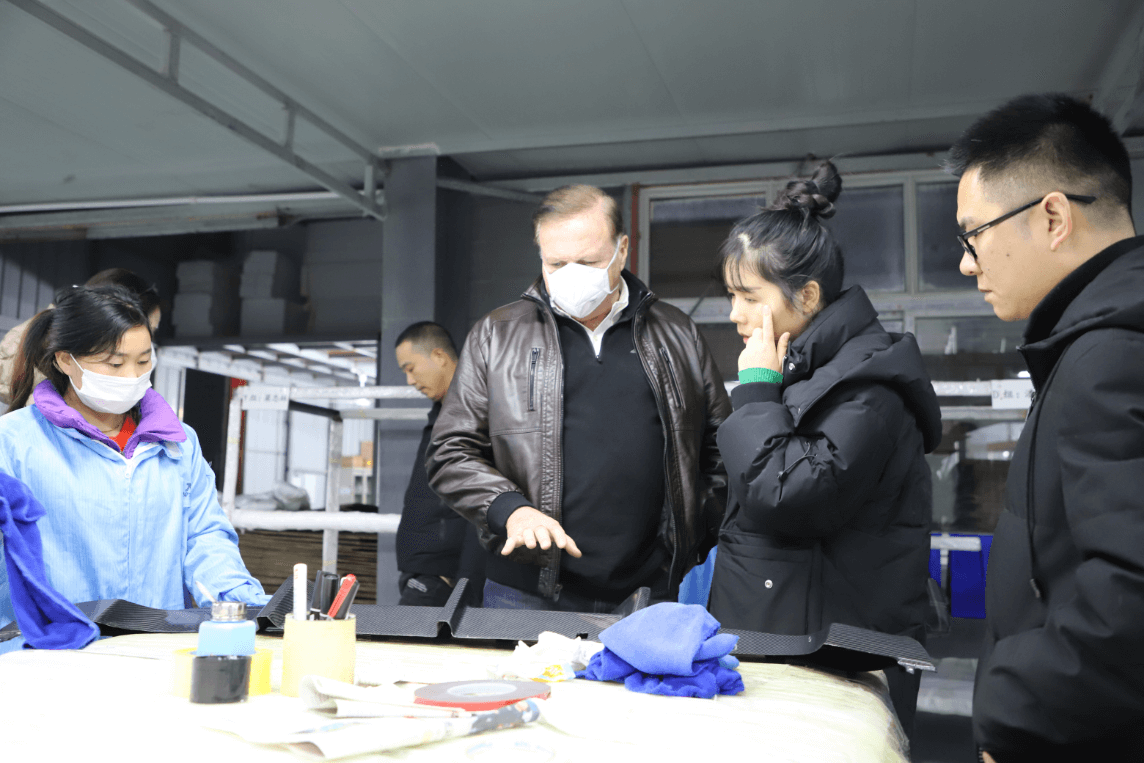

It was truly an honor for our team when our American client Mr. Bob visited the JCSports factory with his team. This visit was a kind of informative and astonishing for our client who gets inspired by our strength, capabilities, and high standards of quality control. carbon fiber trunk/trunk lid spoiler/front bumper canards From raw material warehouse to the finished products warehouse visitor team inspected every step from beginning to the end. JCSportsline uses the most advanced technologies to design and manufacture our products. hood cars/custom car hood/bumper lip splitterThis range of technologies includes 3D scanning, 3D design technology, 3D printing technology, vacuum coating technology, CNC processing and automation technology to skip the biggest problem of non-standard molds and bad installation.

Introduction with production hub:

Our production base in Hubei covers an area of 100mu. Our factory building covers the area of 30,000 square meters. Our production team is comprised of more than 300 workers with 20 design teams, 20 mold making masters. JCSportsline is a highly scaled carbon factory in China and it is the only aftermarket company with environmental protection and TS16949certification.

Raw material warehouse:

In our raw material warehouse, we had shown them the high-quality raw material we use for our products.front bumper lip splitter/custom diffusers/truck rear diffuser/headlight eyebrows Carbon fiber we use is attributing to high axial strength, excellent performance, and modulus. It is with excellent temperature resistance performance and high strength to weight ratio.

Autoclave workshop:

In our autoclave workshop, they observed dry carbon molds. We explained to them that carbon fiber parts construct similarly as fiberglass parts. Molds cover in a release agent put fiber in a place and covered with epoxy. The components of carbon fiber use woven mats of material that buildup multiple layers. To hold the layers together we use vacuum bags.

Prefacing CNC technology:

CNC technology is the key to make modern automobiles safer than before. With CNC technology, we assure computerized cutting, boring, drilling options for production and prototyping of automotive parts. High performance is the basic demand of every facet of manufacturing technique. eyebrows for car headlights/side splitters car/car side skirtWe produce precise and highly efficient body parts with our 5 CNC machining machines. JCSportsline ensures the speed, repeatability, precision, and accuracy with CNC automotive instead of conventional machining.

Finished products display:

After visiting the manufacturing process plant our visitors give a check to our final finished products sport car body kits wholesale/bodykit shops wholesale. JCSportsline is cooperating with BMW, Benz, Audi, and other sports car brands, on tuning market for carbon ABS Customized tuning parts. With the experience of over 10 years, our company is providing phenomenal services for OEM upgrading parts/brand tuning parts/ 4s car shops/ car accessory distributors/ car repair services/ car tuning shops/ used car dealers, with our top quality carbon fiber body kit, engine hoods, spoiler wings, mirror covers, grill, etc. It was a really satisfying experience for Mr. Bob and his team. They were quite impressed with the technology and efficient working environment of JCSportsline.

Quality control:

During the visit of our quality inspection department, we had shown them how our QC team performs quality inspection of finished products and generates a strict quality report for each part.

Ware House:

In the end, our American client visited our big stock warehouse that is about 5000SQM long. To improve production efficiency and regulate the production operation procedures and to ensure the safety of products, we control the quality and legality to ensure the on-time delivery of products.

A brief demonstration:

After the complete visit of JCSportsline, we introduced our guests with our R&D team, skilled technology engineers, and developing group. custom body parts wholesale/autobody kits wholesale We briefly described them about our newest state of the art machinery and all the strong key factors which give us a great ability and big capability to provide marvelous quality products on a global scale.

A word from JCSportsline:

JCSportsline is working from the very first day for the satisfaction and convenience of our clients. We aim to supply quality products for the automobile industry. We are always available for our loyal customers and offer to visit and witness the quality we claim for.

Copyright © 2019 JCsportline Co., Ltd. | All Rights Reserved