Jcsportline is not only the biggest carbon car parts manufacturer,but also your carbon tuning parts solution partner

Nowadays, with the information explosion, it is easy to find different carbon fiber suppliers' information through various channels, but how to judge whether the carbon fiber manufacturers are the ones that really meet your needs? Maybe a lot of suppliers feel the website, and pics are ok, but just a middleman, or only a few workers in a small workshop without any standards and production qualifications, according to JCSPORTLINE 20 years of experience in the composite industry and manufacturing, you only need to ask them 3 questions and let you see the process with your own eyes, then congratulations, you really find the strength to become your partner to empower your business!

One of the key aspects in determining the capability of a company as a reliable supplier of carbon fiber automotive parts is the use of original vehicle 3D scanning to ensure precise product fitment. This advanced technology involves the use of high-precision laser scanners to capture the geometric data of the vehicle and convert it into a digital model. By conducting an original vehicle 3D scan, suppliers can accurately understand the external and internal structure of the car, ensuring that the carbon fiber parts they provide are perfectly aligned during installation.

The process of original vehicle 3D scanning typically involves scanning the entire vehicle using high-accuracy laser scanners, capturing details of the body, interior, and engine compartment. The resulting scan data is then processed and reconstructed to create an accurate digital model that can be further analyzed and designed on a computer.

There are several advantages to utilizing original vehicle 3D scanning:

Precision: Original vehicle 3D scanning captures the intricate details and complex shapes of the vehicle, ensuring that the produced carbon fiber parts perfectly match the installation position of the original car. This eliminates the possibility of human measurement errors, providing higher precision and consistency.

Reliability: By conducting original vehicle 3D scanning, suppliers gain access to precise vehicle data, avoiding uncertainties associated with manual measurements and drawings. This establishes a reliable foundation for designing and manufacturing the parts, ensuring their reliability and stability during actual installation.

Calibration fitment consistency: Match the original 3D car data with the molding, sample, and bulk orders together, to make sure there is no deform problem during molding, sample, or bulk orders.

Inspecting factory videos with real people appearing in them is a crucial aspect when assessing the credibility and capability of a company as a carbon fiber automotive parts supplier. This practice ensures transparency and gives customers confidence in the quality and authenticity of the manufacturing process.

When evaluating factory videos, the presence of real people adds an extra layer of reliability and trustworthiness. It demonstrates that the company is willing to showcase its facilities, operations, and employees, allowing customers to see firsthand how the production of carbon fiber parts takes place.

Moreover, real people in the videos allow customers to witness the attention to detail and precision involved in the manufacturing process. They can see firsthand the dedication and professionalism of the employees, which further instills confidence in the company’s ability to deliver high-quality carbon fiber automotive parts.

Inspecting factory videos with real people appearing in them also helps customers evaluate the company’s commitment to ethical practices and social responsibility. It showcases the working conditions and treatment of employees, providing customers with insights into the company’s values and corporate culture.

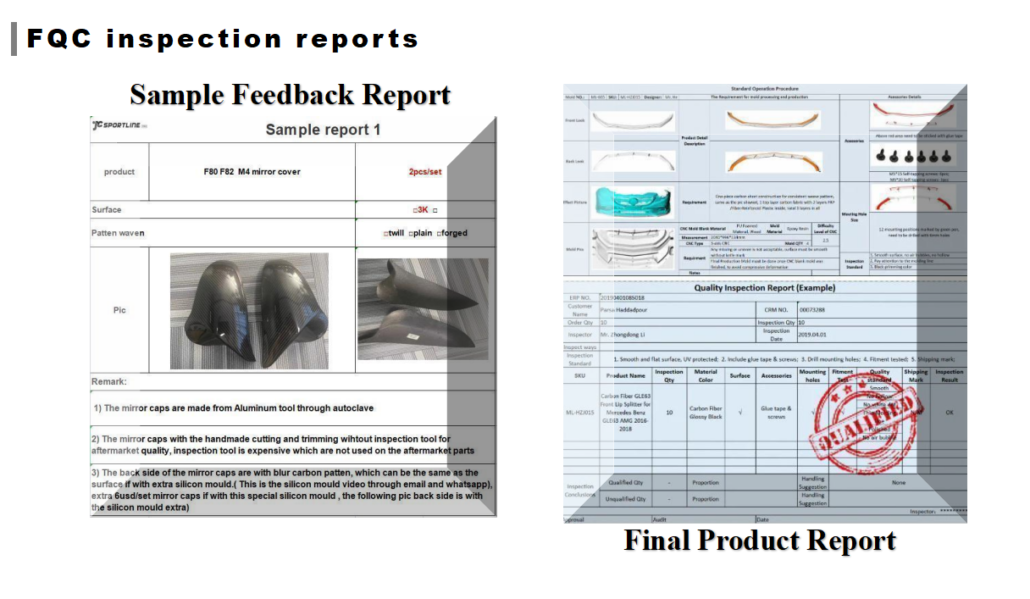

A reliable carbon fiber automotive parts supplier should have a documented quality management system (QMS) in place. This system ensures that all processes, from raw material sourcing to manufacturing and quality control, adhere to established standards. Look for certifications such as ISO 9001, which indicates compliance with internationally recognized quality management principles. The presence of a QMS demonstrates the supplier’s commitment to delivering consistent and reliable products.

In conclusion, when searching for a reliable carbon fiber automotive parts supplier, prioritize product fitment, verify factory videos with real people, and check for the existence of a quality management system. By considering these aspects, you can make an informed decision and choose a supplier that meets your expectations for quality, craftsmanship, and customer satisfaction.

Copyright © 2019 JCsportline Co., Ltd. | All Rights Reserved